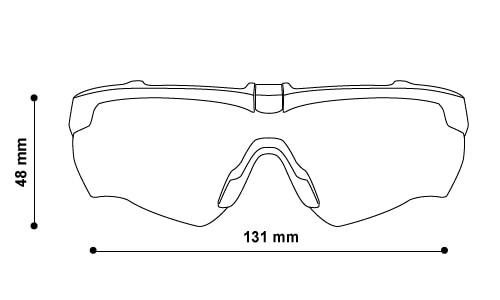

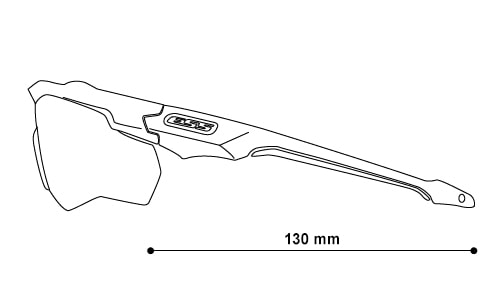

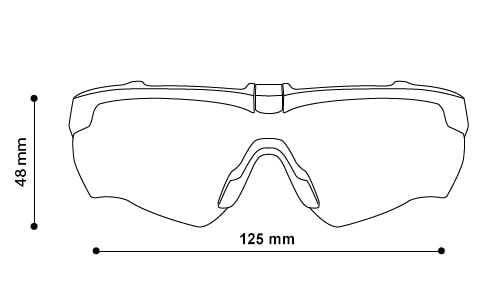

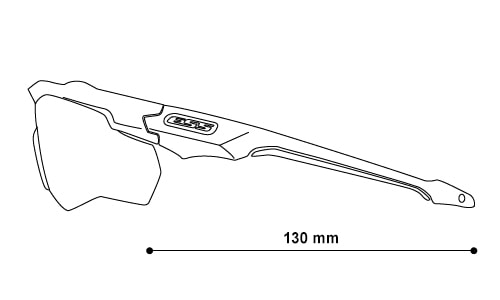

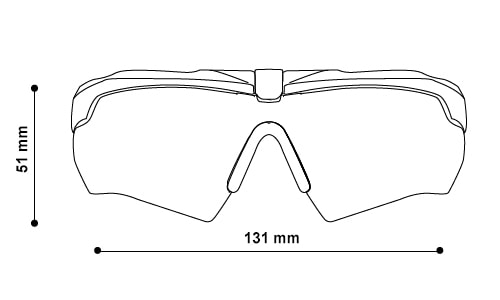

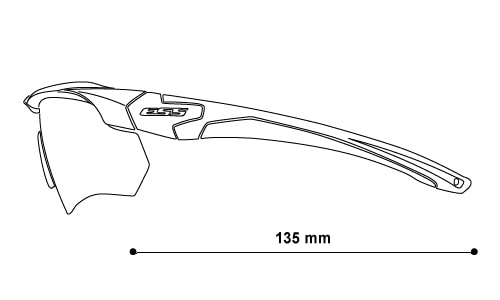

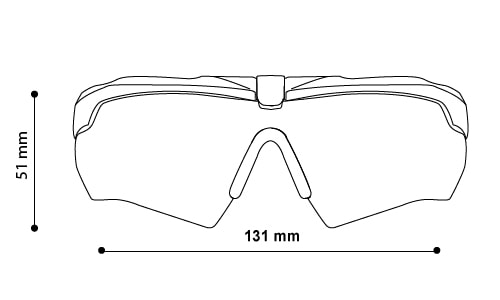

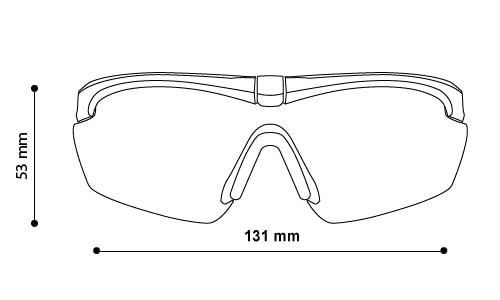

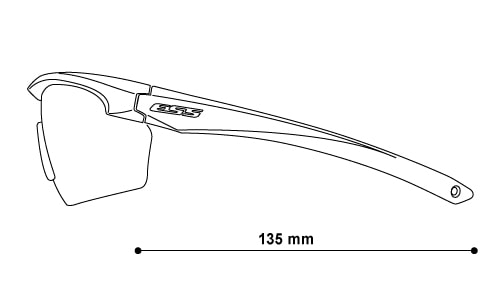

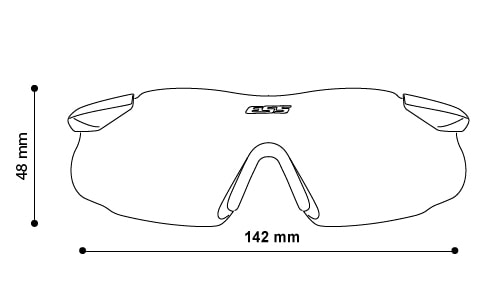

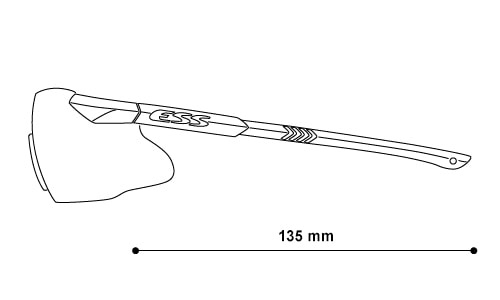

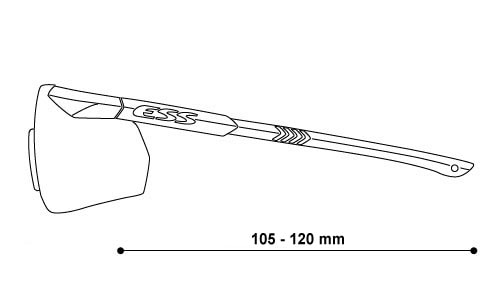

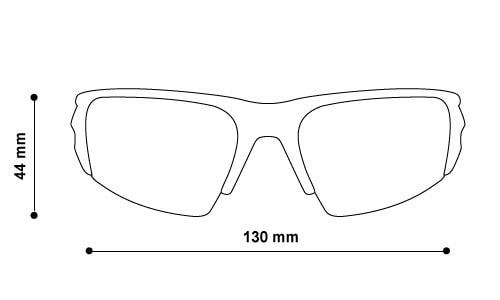

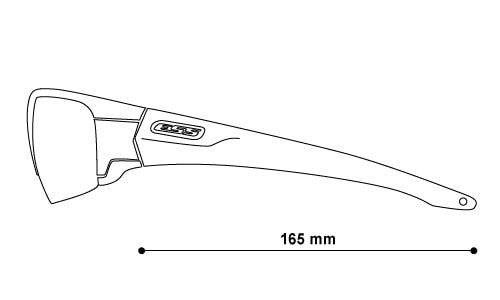

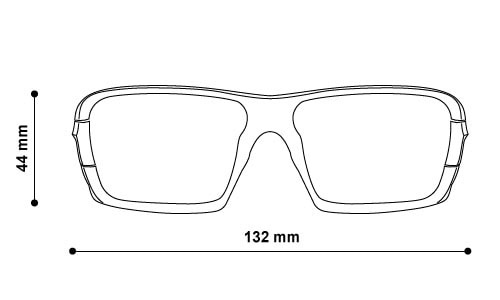

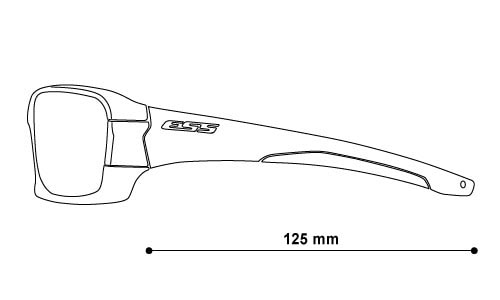

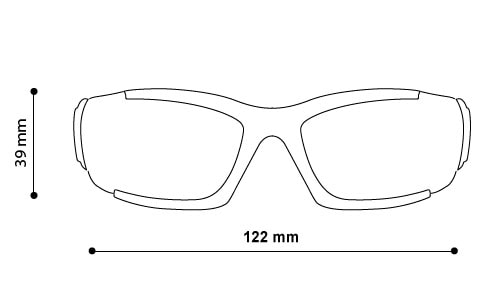

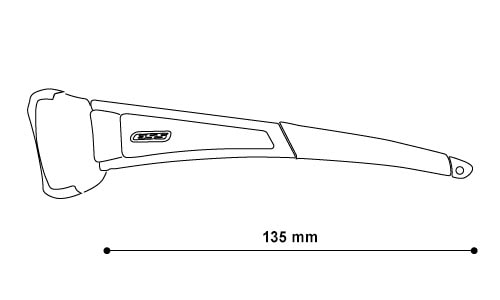

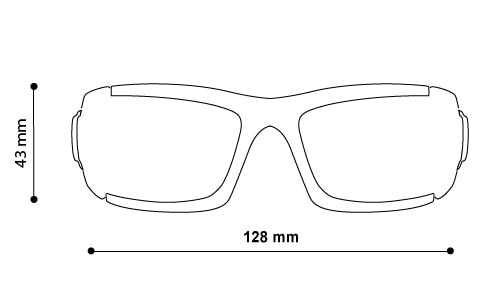

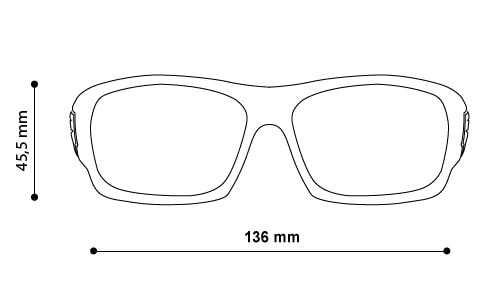

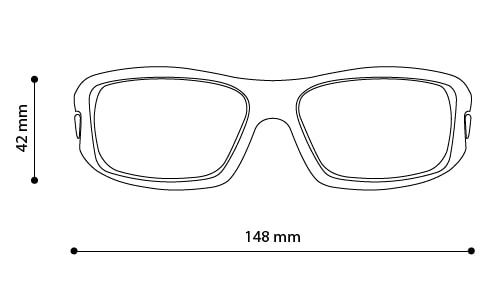

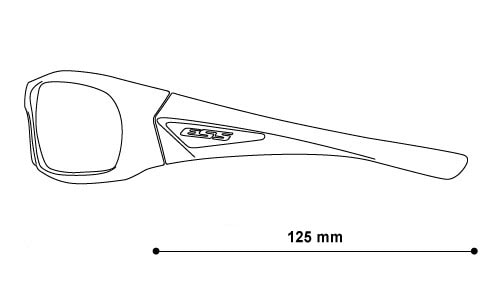

Lens card and ESS glasses sizes

ESS (Eye Safety Systems) is a leading supplier of glasses and goggles to the U.S. Army and military, police, fire and emergency services in more than 100 countries worldwide. Created to protect its users in the most unfriendly environments known to us, ESS glasses and goggles have been designed using the latest technology and patented solutions.

At the heart of the company's strategy is to create high quality products tailored to the specific needs of its users, providing them with products that provide eye protection at the highest level. ESS products are NATO compliant, have NSN numbers and are listed on the NATO Logistics Stock Exchange (NLSE) - NAMSA.

ESS glasses and goggles are manufactured in the USA in ISO 9001-certified factories and have a two-year warranty covering manufacturing defects and quality. The motto of the company is Built for Battle. Tough for Life.

LENS CHART

(VLT) Visible Light Transmittance

VLT (Visible Light Transmittance) is the percentage of light passing through the eyepiece viewfinder. For example, a model with a VLT of 23 transmits 23% of visible light (not to be confused with UV), blocking the remaining 77%. The lower the VLT value, the dimmer the viewfinder.

Follow the guide below to choose your glass color and VLT ratio taking into account the conditions you are most often in. Regardless of VLT, all ESS lenses provide 100% UVA / UVB protection.

NOTE: The lens colours shown in the chart are only a visualisation and may not match the actual product colour. The colour availability of the lens varies depending on the model selected.

PHOTOCHROMIC

Photochromic

VLT: 86 - 24

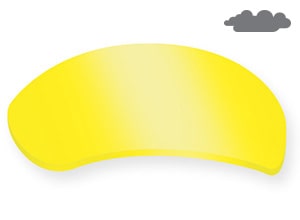

HI-DEF YELLOW

High Contrast Yellow

VLT: 85

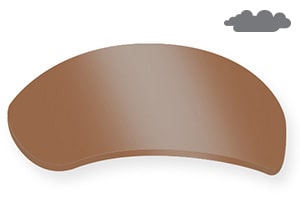

HI-DEF BRONZE

High Contrast Bronze

VLT: 62

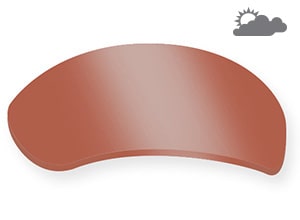

HI-DEF COPPER

High Contrast Copper

VLT: 32

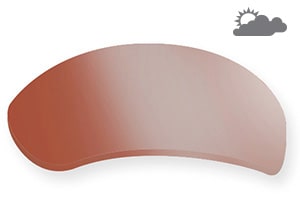

MIRRORED COPPER

Mirrored Copper

VLT: 23

SMOKE GRAY

Smoke Gray

VLT: 15

POLARIZED GRAY

Polarized Gray

VLT: 15

MIRRORED BLUE

Mirrored Blue

VLT: 13

MIRRORED GRAY

Mirrored Gray

VLT: 12

POLARIZED MIRRORED BLUE

Polarized Mirrored Blue

VLT: 11

IMPACT RESISTANCE

High Velocity Impact

ESS goggles and goggles exceed the high-speed impact protection test of the American National Standards Institute (ANSI). According to ANSI Z87.1, the quarter-inch steel BB is shot from three different heights and at seven different angles. To pass the test, contact between the lens and the eye is not permitted during impact. In addition, no part of the frame or lens shall fragment during an impact.

High mass impact resistance

ESS goggles and goggles also exceed the requirements for protection against high weight impacts. As part of the ANSI Z87.1 heavy-duty impact test, the viewfinder is struck by a 500 gram metal spike dropped from a height of 130 cm. To pass the test, no part of the frame or viewfinder must fragment during impact.

The military standard means that the glasses will withstand more than 6 times higher kinetic energy than the ANSI Z87.1 standard for safety glasses and goggles. ESS brand ballistic glasses exceed US military standards.

American military standards require ballistic eye protection to be able to withstand:

- for glasses: 700 - 725 ft/s (~213 - 221 m/s) at .15

for ANSI Z87.1 is the impact resistance of a steel BB with a diameter of .25 inch and a speed of 150 ft/s (~46 m/s)

- for goggles: 580 - 590 ft/s (~177 - 180 m/s) at .22

for ANSI Z87.1 is the impact resistance of a steel BB with a diameter of .25 inch and a speed of 250 ft/s (~76 m/s)